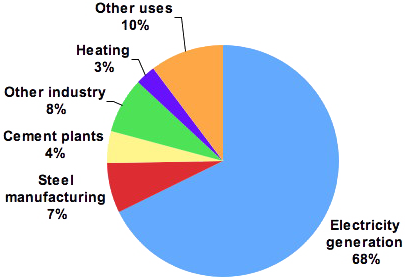

What do we use coal for ? But to have trains ! Of course coal use is not limited to this application, but this introduction is only half a joke, because the three main usages of coal, in the world, are, by decreasing order of importance :

- electricity generation (2/3 of the world coal consumption), electricity being used for a number of things… including powering trains,

- steel manufacturing (about 7% of the world coal), which is then used to build trains, rails, and concrete irons that are themselves used to build stations and tunnels,

- cement manufacturing (4% of the world coal), also used to build stations and tunnels.

And as trains are environment-friendly, coal is also ! Or did I miss something ?

Breakdown by usage of the world coal consumption in 2007.

Source : International Energy Agency, 2009

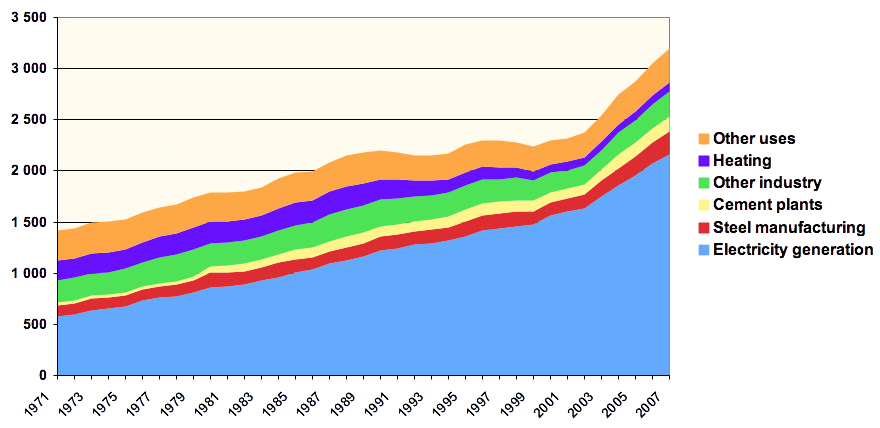

Coal use by sector, from 1971 to 2007, in million tons oil equivalent.

The amount of coal use for power generation has almost quadrupled over the period.

Source : International Energy Agency, 2009

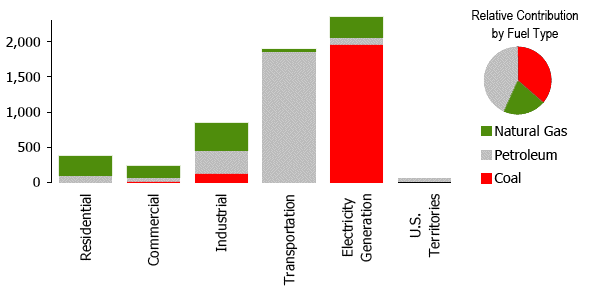

More seriously, these three main uses of coal result in the fact that it is not only an energy for “emerging” countries, but also… an energy for (very) rich countries, because the latter also have coal fired power plants and steel mills. As an exampe, a breakdown of the CO2 emissions by sector for the US, now only the “second” greenhouse gases emitter in the world, will prove it better than a long speech.

Breakdown by sector and energy of the greenhouse gases emissions in the US.

50% of the electric production is due to coal, resulting in a domination of this energy in the emissions of this sector. The US, though being the first oil consumer in the world with 22% of the total (and 70% of this oil goes to transportation), emit almost the same with coal than with oil.

Source : U.S. Environmental Protection Agency, Inventory of US greenhouse gases emissions and sinks, 1990-2005

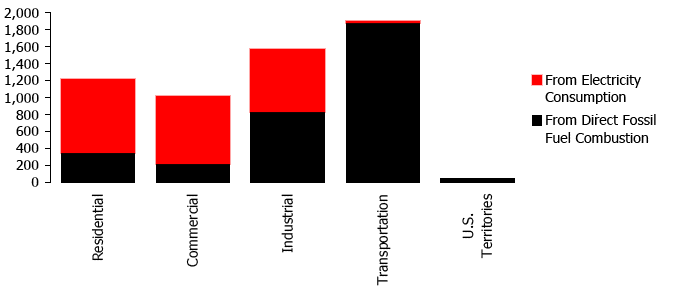

Breakdown of the greenhouse gases emissions in the US by sector and by final energy (the carbon content of electricity comes from the fuels used). “Commercial” designates buildings that are used by commercial and office activities (retail stores, offices, warehouses, education, health, etc).

As coal is the main cause of the carbone content of electricity (see left), and as electricity induce greater emissions for buildings than heating (direct emissions), it means that buildings in the US indirectely depend more on coal than on oil or gas !

Source : U.S. Environmental Protection Agency, Inventory of US greenhouse gases emissions and sinks, 1990-2005

The US is not the only industrial country to use a lot of coal: among the 25 countries that have the highest coal consumption per capita, a number belong to the OECD block !

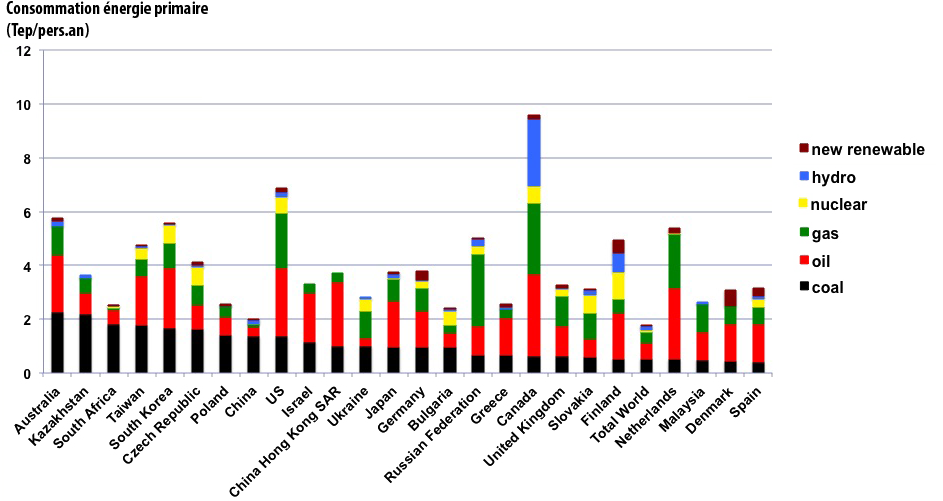

Primary energy consumption per capita in 2012, in tonnes oil equivalent, for the 25 first coal consumers per capita in the world.

A large fraction of the countries represented here are “old industrialized countries”, with the notable exception of China. Note that India does not appear here ; an Indian uses about as much coal as… an Italian or a Swede ! And a Chinese uses less coal than a Pole or a Czech, and less than an Australian or an American.

Source : Author’s calculations on primary data from BP Statistical Review 2013 ; Population Division of the Department of Economic and Social Affairs of the United Nations Secretariat.

When figures are those of the global consumption of countries, then the most spectacular increase comes from China.

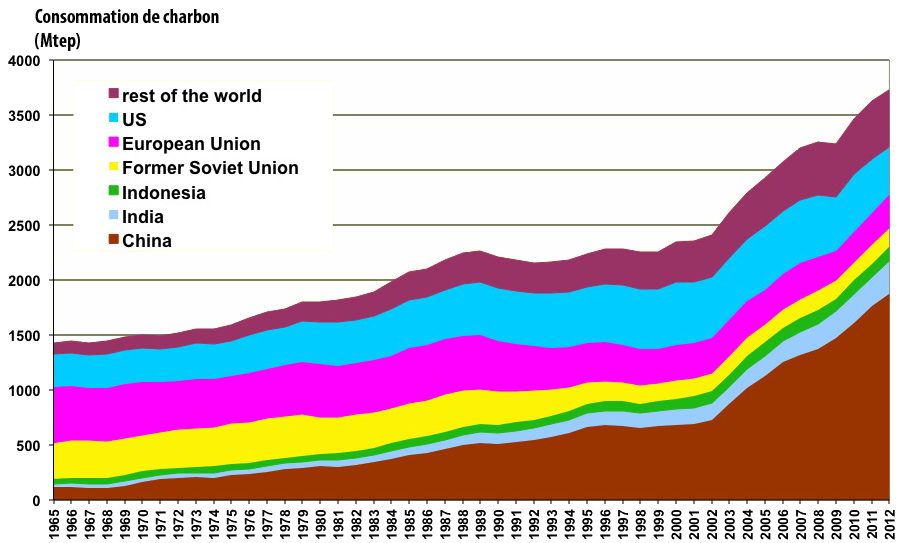

Evolution of the world coal consumption since 1965.

Russia came first in 1965 (it has the second largest coal reserves in the world). Then the US “took the lead”, then China, who used 50% of the world total in 2012.

Source : BP Statistical Review, 2013

Coal and coal

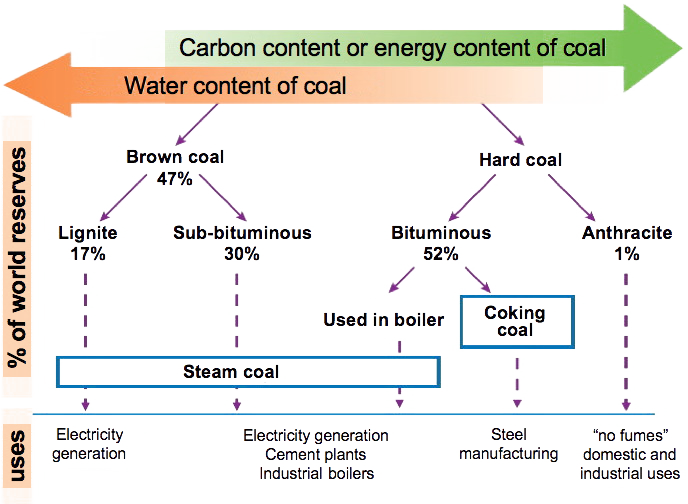

Coal definitely allows less usages than a swiss army knife, since it is mainly used for electricity, steel and industrial heat, but this variety is enough to strongly discriminate the destination of coal depending on its quality. Because there are various grades of coal, just like there are various grades of oil, and it is not possible to use any grade of coal to fuel any process that requires coal. For oil, what characterizes the quality is density, and for coal it is merely the carbon content.

Various types of coal, with the share in the world proven reserves, and the possible uses.

Source : IFP Panorama, 2010

If coal is not pure carbon, what else can be found in it ? Well… all that was present in the ferns of the carboniferous that led to coal, less the methane that escaped during coal formation. It includes water, both “non associated” (it evaporates at ambiant temperature) and “associated” (it evaporates when the coal is strongly heated), non combustible elements that will turn into ashes, and volatile coumpounds, that is gases that are adsorbed onto the coal during its formation, some being combustible and other not.

Components of coal

| Lignite | Sub-bituminous | Bituminous | Anthracite | |

|---|---|---|---|---|

| Water content of raw coal | 25-50 % | 14-25 % | 5-10 % | 1-6 % |

| Calorific content (inferior value) of partially dried coal before boiler (air dry) in kcal/kg | 3500 - 4500 | 4500 – 6500 | 6500 – 7800 | 7800 – 8600 |

| same in MJ/kg | 15 to 19 | 19 to 27 | 27 to 33 | 33 to 36 |

| same in kWh/kg | 4 to 5,2 | 5,2 to 7,5 | 7,5 to 9,1 | 9,1 to 10 |

| Average composition | ||||

| Residual water | 19% | 10% | 4% | 2% |

| Volatile components | 40% | 38% | 25% | 8% |

| Percentage of ashes | 30% | 25% | 15% | 5% |

| Carbon and carbon hydrates (flamable) | 20% | 30% | 56% | 86% |

Typical composition of a good-grade steam coal

| Components excluding ashes | Ashes | Volatile components | ||

|---|---|---|---|---|

| Carbon | 73,50% | SiO2 | 48,10% | CO2 |

| Hydrogen | 4,10% | AL2O3 | 30,10% | CH4 |

| Nitrogen | 1,70% | TiO2 | 1,10% | H2O |

| Chlorine | 0,17% | Fe2O3 | 6,30% | H2 |

| Sulfur | 0,59% | CaO | 10,40% | Ar |

| Oxygen | 7,00% | MgO | 2,10% | |

| K2O | 0,70% | |||

| Na2O | 0,40% | |||

| P2O5 | 0,40% |

The carbon content of coal discriminates steam coal and coking coal :

- to produce steal, it is necessary to produce coke first, and cokeis almost pure carbon. To achieve this coal to coke transformation a high grade coal is required, with a high carbon content.

- to fuel a power plant it is possible to use about any quality of coal (actually anything that burns !).

But… “burning anything” can bring in another constraint, which is that when going from anthracite to lignite, the energy content per unit of mass decreases, and therefore the energy loss due to transportation (which depends on mass, and not on energy content per unit of mass) increases. The energy content of anthracite is about 10 kWh per kg, when lignite has about half when dried (lignite has more water, more ashes, etc). As a result, using lignite to produce electricity can only be done when the power plant sits on the top of the mine: if lignite has to travel significantly between the mine and the power plant, transportation costs become huge, both with an energy perspective and an economic one.

Even steam coal cannot be transported by road: the only way to transport coal over long distances if the name of the game is not to spend more energy and money through transportation than the content of coal is by boat or train. It explains, along with cooling needs, that a number of power plants are built next to a harbor. In the US, one of the reasons why trains are still significant in the total freight is rail transport of coal !

Coal and electrons

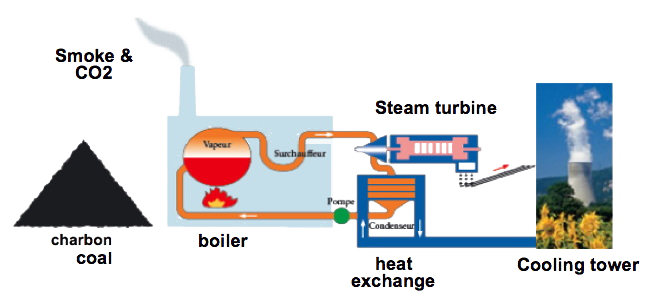

So the dominant usage of coal is to fuel power plants. A coal fired power plant is actually… just a giant kettle ! Indeed, the heat produced by coal combustion is used to produce steam, that will power a turbine. Going from heat to electricity is also what is done when electricity is produced with gas, heavy fuel oil, or… nuclear power. 85% of the world electricity production is therefore done with big kettles, that all need, Carnot said it, a cooling system.

Basic representation of the processes involved into a coal power plant.

Ash removal is not represented.

Source : Bertrand Barré

As a result, when a French sees a cooling tower, he or she thinks “nuclear”, but when you show the same tower to an American, he or she will think “coal”. And when there is a heat wave and low water flows in rivers, it leads to the same restrictions in power production with coal and nuclear.

These cooling towers suggest a nuclear power plant for a French…

… and here is a coal fired power plant, with the same towers !

The quick way to distinguish a nuclear power plant from a coal fired one is not with the cooling system, but with the existence – or not – of huge chimneys, that are here in the centre of the picture.

Coal fired power plants have another specificity: they produce massive quantites of ashes. A 500 MW (electric output) plant , producing 8000 hours in the year (that counts 8760 hours), will generate about 4 TWh of electricity in the year (4 TWh = 4 billion kWh ; 4 million MWh), and with bituminous coal (8 MWh of heat per tonne ; about 3 MWh of electricity per tonne), it means :

- bringing 1,3 million tonnes of coal,

- removing 200.000 tonnes of ashes (that is 50 grammes per kWh). Most often, these ashes are used as construction material for roads or infrastructures alike.

With lignite (4 MWh of heat content per metric tonne; about 1,3 MWh of electricity per tonne), it then means :

- bringing 2,5 million tonnes of lignite to the plant,

- removing 750.000 tonnes of ashes (that is 120 grammes per kWh).

In both cases, it also means mine workers, with several thousand casualties each year (figures vary depending on the source, but the magnitude remains the same), and it is likely that for chinese coal mines – 45% of the world production – accurate and reliable statistics are not that easy to find. If we suppose that 6 000 mine workers die at work each year, and that two thirds of coal is used for generating 8000 TWh of electricity (see below), we get 0,5 casualty per TWh. A 500 MW power plant generating 4 TWh in a year therefore “generates” 2 deaths per year.

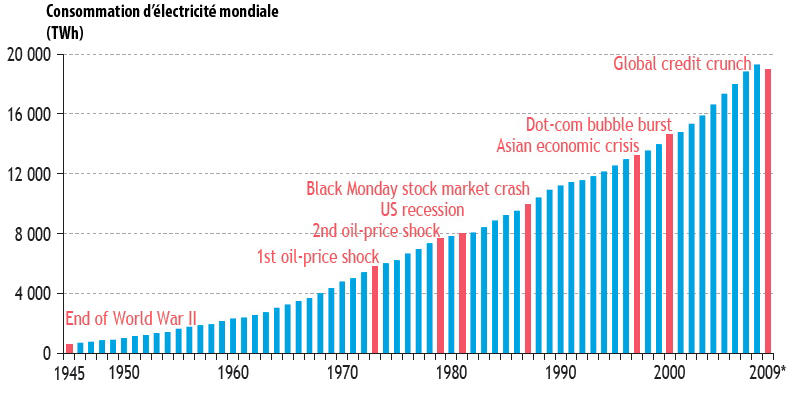

Be it produced with coal or nuclear, we love electricity. Since the end of the Second World War, the world consumption grew from 500 to 20.000 TWh, which means a multiplication by 40. The average electricity consumption per capita has risen from 400 to 2900 kWh per year, and it is the type of final energy that grew the fastest over the period.

World electricity consumption since 1945, in TWh.

Source : International Energy Agency, World Energy outlook, 2009.

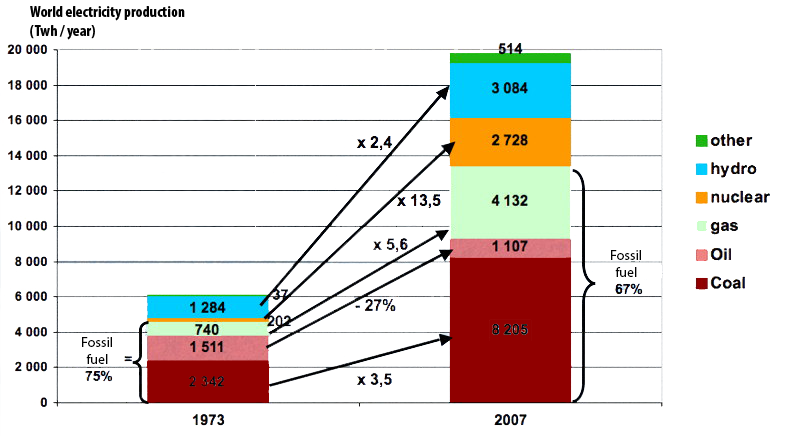

From 1973 to 2007, electricity generation from coal has more than tripled, and, if gas and nuclear have had higher growth rates, the highest increase in absolute figures did come from coal, generating a high increase of CO2 emissions.

Electricity generation in 1973 and 2007, depending on the primary energy used.

Coal has been representing 40% of the total over several decades. Oil has strongly decreased in relative terms, but not that much in terms of TWh generated.

Source : International Energy Agency, key energy statistics, 2009.

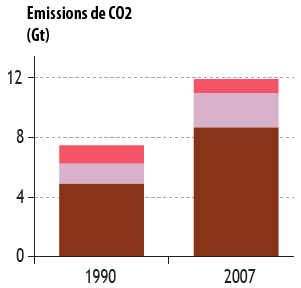

CO2 emissions associated to electricity generation, in billion tonnes per year (coal in brown, gas in purple, oil in red).

With 40% of the world electricity generation, coal represents more than 8 billion tonnes of CO2 per year, that is 20% of the world greenhouse gases emissions.

Source : IEA, World Energy Outlook, 2009

A consequence of calling that much on coal to produce electricity is that CO2 emissions coming from this single use represents more than what comes out of all car exhaust pipes…

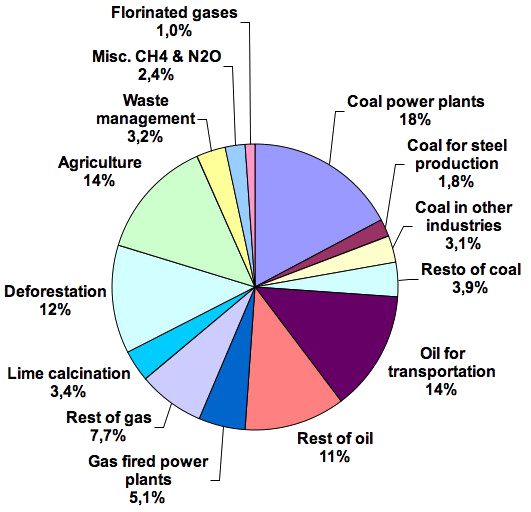

Breakdown of world greenhouse gas emissions in 2004.

Lime calcination is the process done in cement production (lime is heated over 1000 °C, and the calcium carbonate molecules are broken in calcium oxide and CO2). Alors with the emissions coming from the fuel used (coal or petcoke, the last being a residue of oil refining), cement production is therefore generating close to 5% of the world emissions, that ios half of the emissions coming from all cars and trucks, or twice those coming from planes.

Source : Author’s compilation on CDIAC (lime calcination), Houghton et. al 2005 (déforestation), IPCC AR4, International Energy Agency, BP statistical review.

And tomorrow ? Someone naïve might think that, when two thirds of the heads of state in the world did come to an international conference to discuss climate change (Copenhaguen), it means that there is a pause in the construction of coal fired power plants. Not the least !

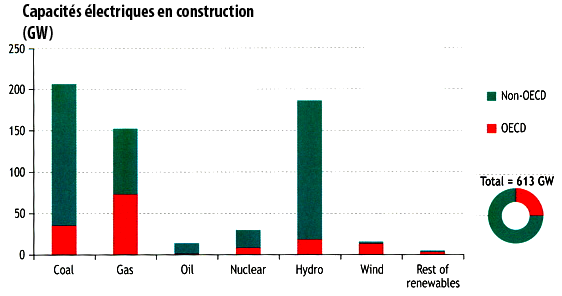

Breakdown by nature of primary energy of the power plants in construction in 2007 (in GW, not in number of plants).

100 GW corresponds to the total installed capacity of a country like France. A nuclear reactor = 1 to 1,4 GW ; a coal plant = 0,25 to 1 GW ; a large dam = 0,5 to 5 GW – 16 for the Three Gorges ; a large windmill = 0,005 GW).

Coal comes first, followed by gas, knowing that gas plants are generally used less in the year than coal plants.

Regarding capacities under construction, wind represents a tenth of hydroelectricty (in 2007). Even though wind increases faster, hydro is still more important in the real world, but not in the paper !

Source : Platt’s World Electric Power Plant Database, December 2008, in World Energy Outlook, 2008, IEA

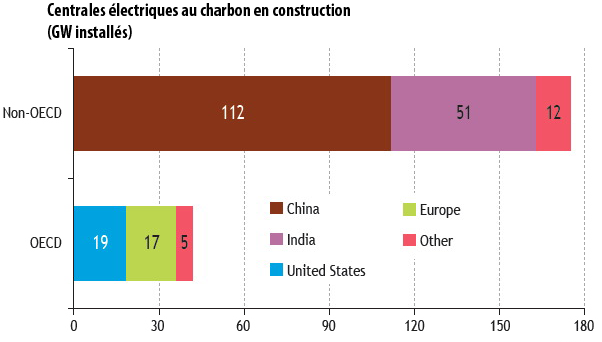

Breakdown by region of the coal power plants under construction in 2007, in GW.

China is obviously coming first, but the US, though already the first electricity consumers in the world (with 20% of the world total), and already among the first in terms of consumption per capita (in the countries that count more than 5 million inhabitants, only Canada comes before, and an Americain consumes almost 5 more times than a Chinese). As they also have a slightly rising consumption per capita (7% extra between 1990 and 2009), they are still building extra coal fired power plants.

Even Europe, that has strong ambitions in the reduction of CO2 emissions, keeps building such plants !

Source : IEA, World Energy Outlook, 2009

If coal takes such a share of electricity production, it is not only because it is promoted by devilish individuals only dreaming of getting rid of a stable climate, it is also because a little something plays a little role: it is the cheapest way to produce electricity at current prices.

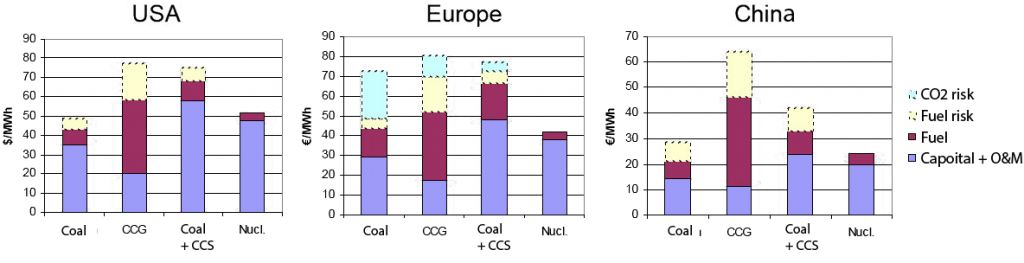

Average cost of electricity, depending on the region, for plants built today.

Each graph compares a standard coal fired power plant, a gas fired combined cycle, a coal plant with CCS, and a nuclear reactor. The combined costs of the initial investment (interests included) and the operations & maintenance (without the fuel cost) is represented by the bottom part of each bar (in blue), then comes the fuel cost (in violet), and the yellow and green parts respectively represent :

- a “fuel risk” extra cost (that is a potential rise of the cost of the fuel due to either a rise in extraction cost, or a decrease in the overall available quantites for the region in which the plant is).

- a “CO2 risk” extra cost (that is the potential cost rise if CO2 emissions are priced at 30 euros per tonne).

These calculations have been performed with the following hypotheses :

- 7000 hours of production per year,

- Interest rates at 6% per year in China, 11% per year in Europe and 13% per year in the USA.

- A coal price of 30 to 50 $ per tonne in the USA, 60 to 80 € per tonne in Europe, and 30 to 60 € per tonne in China

- A gas price of 8 to 12 $ per million BTU (a million BTU = roughly 1 GJ or 300 kWh) in every zone.

Regarding capital costs, we talk of 1500 to 3000 $ per kW of electrical power (not to be confused with a kWh of energy !) for coal plants, 2 to 3 times less for a gas plant, and a little more – 2000 to 4000 $ – for a nuclear plant. In the last case, as the construction time is longer, financial costs are higher for a same capital spending. It is easy to see that without any CO2 penalty, and with a limited price risk for coal, it is this “dirty” fuel which turns out to be the cheapest in China and the US, when in Europe it is break even with nuclear.

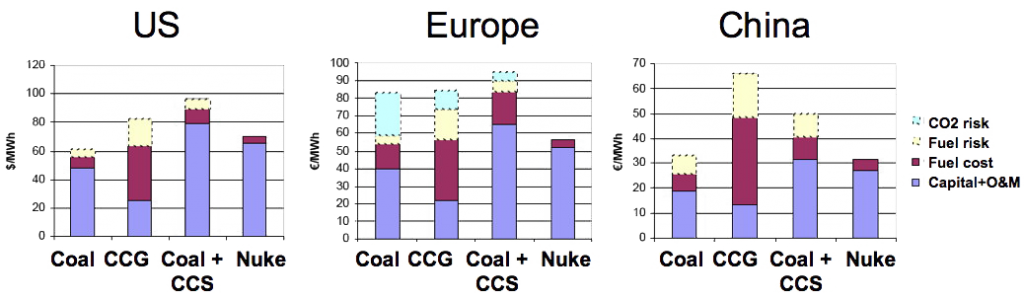

Same calculation as above, for 5000 hours of operation per year (semi-base). Without any penalty for CO2 emissions, coal remains the most competitive in China and the USA.

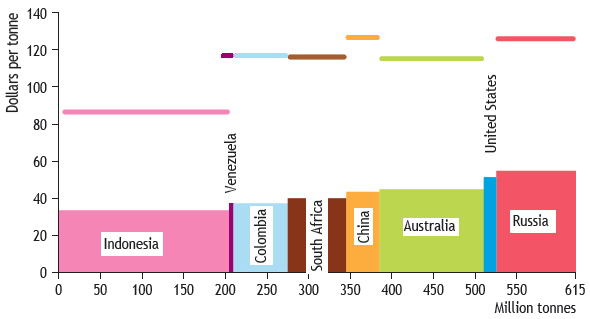

As the above calculations are done with coal costing anything between 30 and 100 dollars per tonne, one might wonder whether we are consistent with the current prices. Well, just ask !

Production costs per tonne (bottom bar) and FOB cost (Free On Board, that is once boarded on the boat or train that will bring the coal to the client, but without the transportation cost), depending on the producing country. These costs are normalized for a heat content of 6000 kcal per kg.

It is easy to see that most of the cost of imported coal is not due to production, but to “other things”.

Source : IEA, 2009

We then wee that these costs are in line with the current price, and, contrary to oil, there is no specific reason for the production cost of coal to rise massively within the next 20 years. A a logical result of the cheap price of coal, its availability in large amounts, and the possibility to turn it into electricity, the coal consumption per capita has never been as high than today.

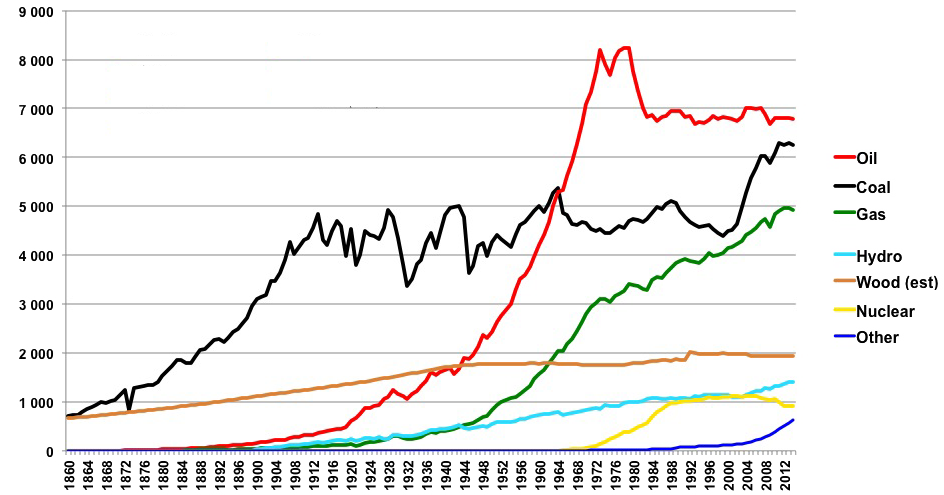

Average consumption per capita for each significant energy from 1860 onwards, in kWh per year.

Oil and coal are about to cross….

Source : Shilling et al., 1977, BP Statistical Review, 2012, and United Nations for the population

Of course, this average does not reflect regional differences, including the fact that the first consumer in the world is, by far, China, after it has been the US for a long time.

Steel, then

Another significant use of coal is steel manufacturing. Steel is the first metal produced in the world, with roughly 1,4 billion tonnes in 2008 (including production from scraps), what required 500 million tonnes oil equivalent to be done (4% of the world consommation of energy). This production relies on a pretty simple process: Mother Nature has endowed us with a comfortable stock of iron ore, which consists in various oxides deposited in a number of places below the ground.

We just have to dig (to extract the ore and the coal), then mix the oxide with coke, a kind of “refined coal” in a blast furnace. Coke is almost pure carbon obtained from high grade coal (anthracite or bituminous coal with low contents of ashes and water) which is “stripped” of all that is not carbon (volatile compounds and water; removing ashes in advance is not that easy…).

In the blast furnace, the oxygen of the iron oxide will leave the iron (so sad…) to “stick” to the carbon, and form CO2 molecules. To get one ton of pig iron – that will later on become steel – in a blast furnace we need around 700 kg of coal, and produce around 2 tonnes of CO2. Another part of iron production is made with scraps, which does not require coke but “just” some energy (generally electricity). And overall, we also use more and more steel !

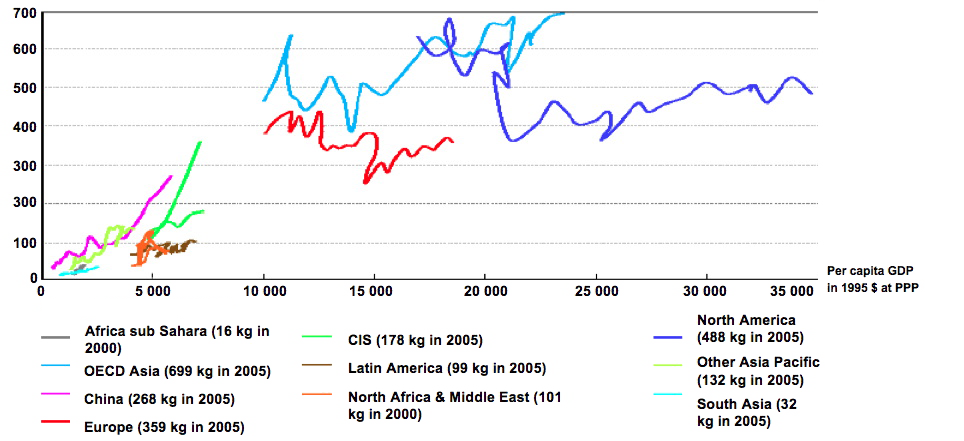

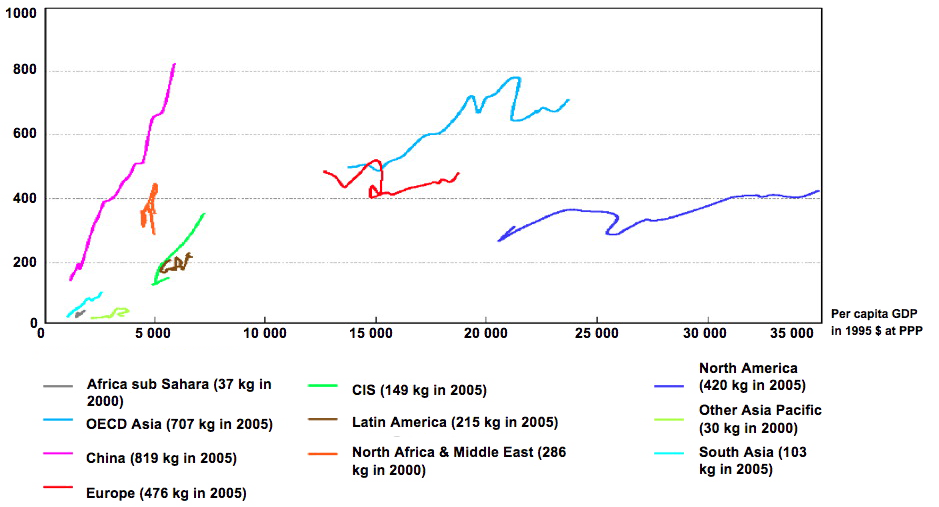

Regional steel production per capita depending on the GDP per capita.

Each curve represents the 1971-2005 period, and does not account for foreign trade (i. e. the steel contained in the imported goods is not accounted for). The values that end the zone names (e. g. 268 kg for China) represent the steel consumption per capita for the year 2005.

Source : Lysen 2006

As we see on the graph above, an European uses roughly 350 kg of steel per year, and as about half is produced with scrap, it means 120 kg of coal per capita and per year. We therefore “consume coal” each time we buy something that contains iron or steel (cars, houses, washing machines, furniture…), and even each time we buy anything that has been manufactured by a company that has steel machines or steel in its buildings ! We even use “embedded coal” each time we take a train…

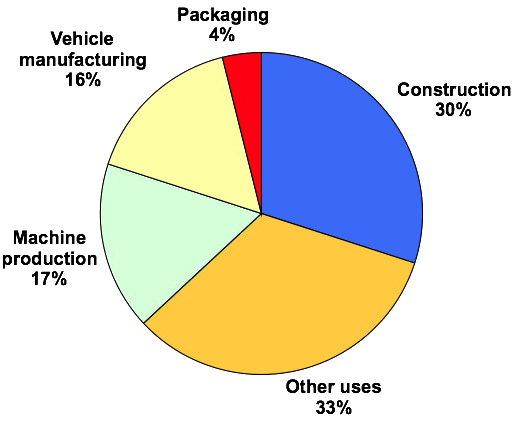

Breakdown by usage of the steel consumed in Europe in 2000.

Source : Eurostat 2001

Then comes cement

Along with steel, the other major industry that is a significant coal user is cement plants.

Regional cement production per capita depending on the GDP per capita.

Each curve represents the 1971-2005 period, and does not account for foreign trade (i. e. the steel contained in the imported goods is not accounted for). The values that end the zone names (e. g. 819 kg for China) represent the cement consumption per capita for the year 2005.

The frantic construction activity in China explains why this country has the first consumption per capita, and then, by far, the first consumption of all countries in the world.

Source : Lysen 2006

Producing a tonne of clinker – the primary component of standard cement – requires 1000 kWh of heat, that is 0,15 tonne of coal when this fuel is used (most common case), leading to the emission of 350 kg of CO2. This does not take into account the CO2 coming from the calcination of the lime, so that the overall emission is closer to one tonne of CO2 per tonne of cement. As a result, cement production accounts for 3% to 4% of the world greenhouse gases emissions, like steel (and steel and cement production combined represent almost as much as road transport).

Can coal travel everywhere ?

You will have noticed also: coal is solid. This basic charactistic has an important consequence: coal is the fossil fuel that travels the least. Only 12% of the world coal production crosses a border between extraction aud use (it is 22% for gas and 60% for oil). Coal is thus baiscally a domestic energy: almost 90% (and it is more than that for steam coal) is used in the country where it is produced. When it is imported, 2/3 of the price paid is transportation costs. It is easier to ship everywhere products made with coal !

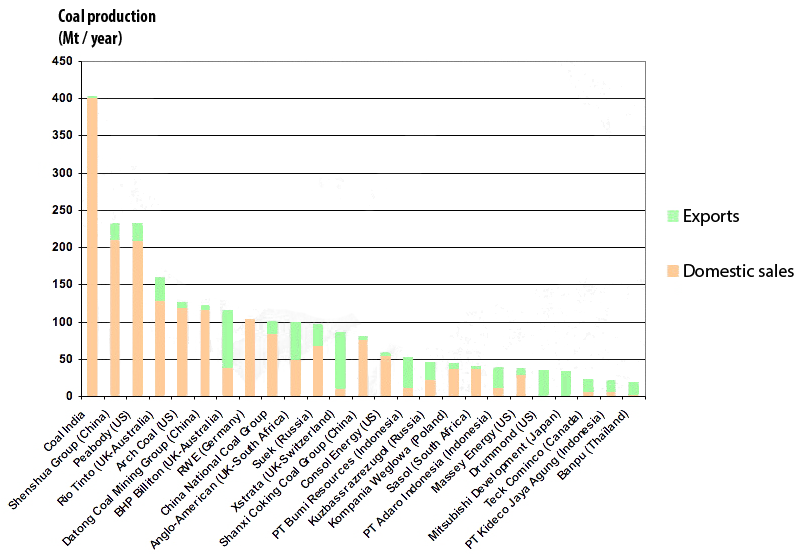

Production of the top 25 coal producers in the world (representing 35% of the world production and almost 100% of the world exports) with the breakdown between exports and domestic sales.

It appears clearly that most producers mostly sell on their domestic market.

Source : IEA, World energy Outlook, 2009

The world trade is mostly done with the highest grades of coal (anthracite, coking coal, bituminous steam coal) and amounted to 650 million tonnes in 2008. Japan, Korea and Taïwan used more than half of the world imports.

And tomorrow ?

In a context where immediate advantages outcome long term inconvenients, it is logical that coal is still a key contributor to the world supply. As price formation does not account for future depletion and long term environmental damage, but only for immediate labour and capital costs, coal is the winning ticket :

- it is abundant, and most of all available domestically in the countries that dominate the world economy (except for Japan),

- it is cheap to extract: 40 to 50 dollars per tonne, and sometims much less, that is 0,5 to 1 euro cent per kWh (same cost than for oil),

- it is the basic fuel – or the cheapest – for the production of all raw materials that have allowed the thriving of industrial societies,

- it allows to produce electricity for the lowest immediate cost, and electricity is the most noble form (and thus the most polyvalent), regarding thermodynamics, of all final energies we use.

With more than 500 billion tonnes of proven reserves, coal would be the last fuel available if fossil fuel consumption continues to grow as today. As oil has peaked or is about to do so, and gas will follow the same kind of path before mid-century, calling more and more on coal will be a growing temptation in a world looking for growth at any price. Of course, this temptation has a price: an aggravated climate change, as coal is the fuel that generates the highest greenhouse gases emissions per energy unit…

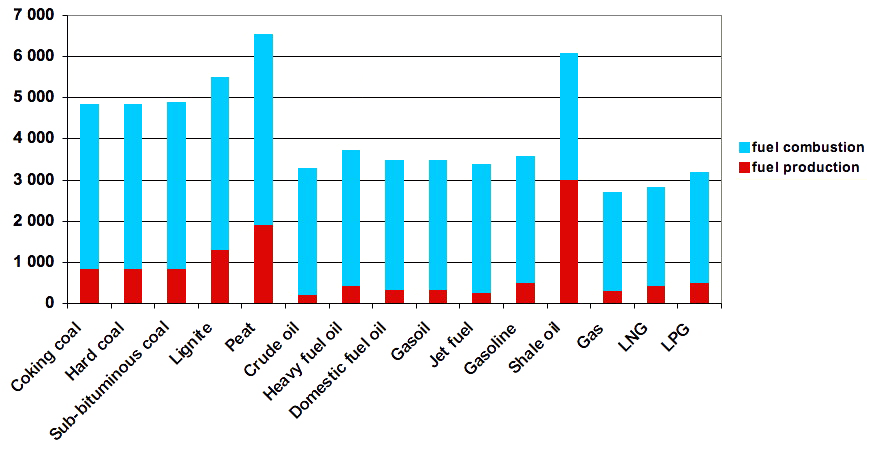

Greenhouse gases emissions for various fossil fuels, in tonnes CO2-equivalent per tonne oil equivalent (the methane coming from the production phase is accounted for).

For each fuel the red bar represents the emissions coming from the upstream phase, that is extraction, transportation, and all other operations associated to production :

- for coal, washing and grinding,

- for gaz, purification, and possible liquefaction,

- for oil, refining.

Source : Ademe, 2010

Even with CO2 capture and sequestration, a growing coal consumption will be hardly compatible with a division by three of the world emissions, which is the prerequisite to any stabilization of the world average temperature.

And even though we would choose to ignore climate change, a growth of coal production cannot be sustained forever : some kind of peak before 2050 is not that unlikely.